Step 1

A seamless inner liner of polyethylene (HDPE) is blow-molded.

A composite LPG cylinder or Type IV LPG cylinder, consists of a fiberglass pressure vessel and an external casing. Composite cylinders are widely used for storing gas under high-and low-pressure.

Composite materials have unique qualities such as light weight, superior strength and increased durability, and they are used in multiple industrial applications.

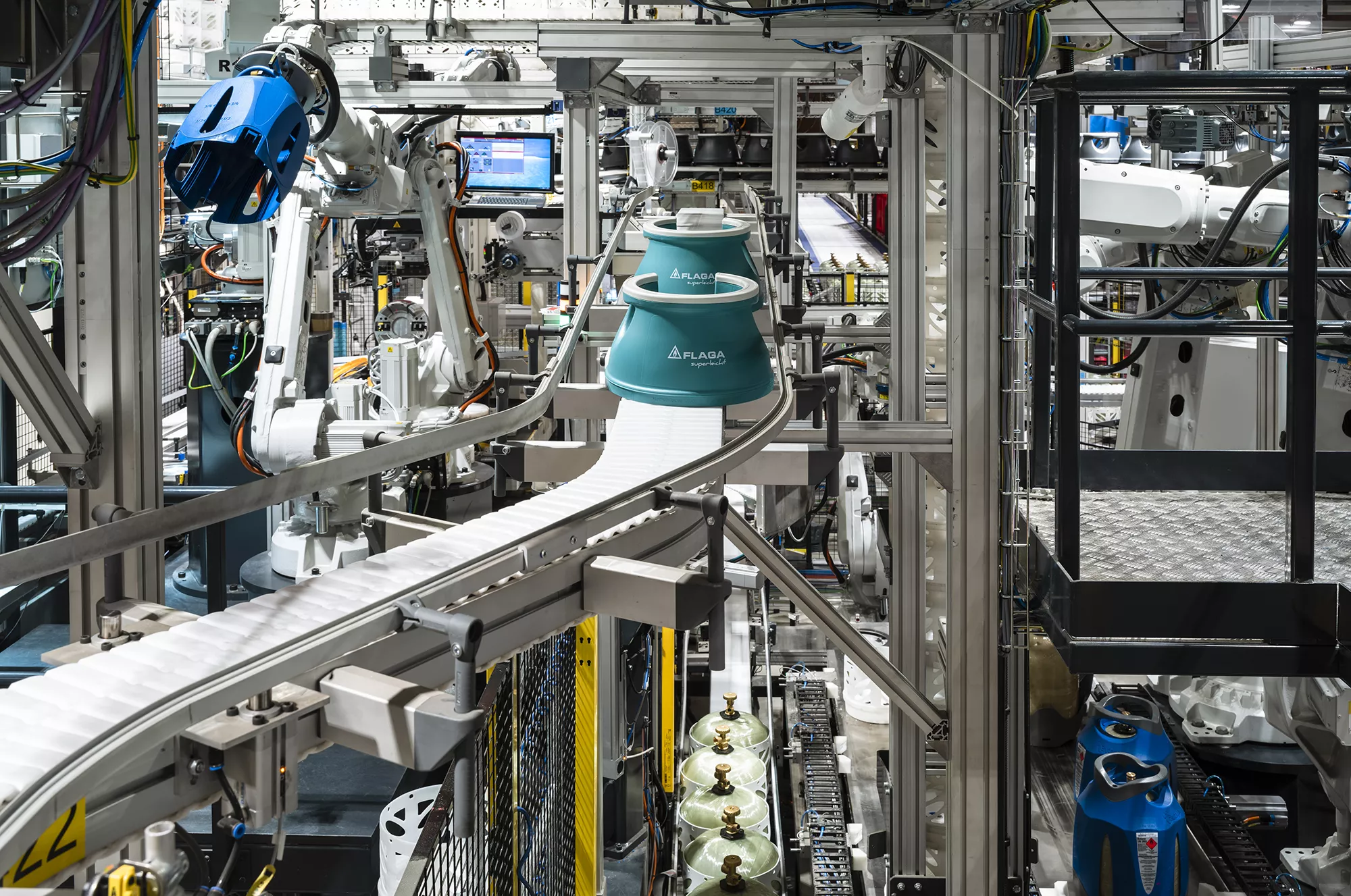

Our cylinders are produced specially for the LPG industry in our fully-automated production plant, and their manufacturing process is comprised of three main steps:

A seamless inner liner of polyethylene (HDPE) is blow-molded.

Glass fibers and resin are then wound around the liner to create the pressure vessel.

To provide even greater support and bring an element of design, we add an outer layer in the form of a polyethylene (HDPE) casing. This distinctive casing, with trademarked design, provides both protection and an ergonomic grip. It also allows our customers to brand their cylinders.

Our entire process is done in-house and fully automated – starting with the raw materials through to the completed cylinders on pallet ready for shipment, making our cylinders, the most efficiently-produced and quality consistent composite LPG cylinders in the world.

During the manufacturing process, there are more than 35 points where production data on each cylinder is collected and stored for full traceability.

Our standards for design and manufacturing of composite cylinders

Approvals & certifications

Our products are approved and certified in close to 100 countries. We are dedicated to the task of achieving local and national approvals and providing support to the local competent authorities.