Environmental Product Declarations

Our Environmental Product Declarations (EPD) are proof of our commitment to transparency and focus on science-based information to evaluate the environmental performance of our products.

As the leading supplier of composite LPG cylinders, we have set ourselves ambitious sustainability goals that cover our entire value chain and are committed to playing an important role in the energy transition toward a cleaner and healthier future.

1,1 %

Our production's contribution to the carbon footprint of the whole lifecycle (LCA)

≈ 100%

Hydro-powered manufacturing (Norwegian energy mix)

20+ years

Proven lifetime of our cylinders (since start of production in year 2000)

"Working with sustainability at Hexagon Ragasco means using a science-based approach to develop and manufacture even more sustainable composite LPG cylinders. We strive to minimize our carbon footprint throughout our product's life cycle and to communicate our results with transparency, to all our stakeholders."

We strive to make bottled LPG available worldwide, thus contributing to transforming lives by improving health, protecting the environment and empowering women by providing them with clean, affordable and readily available cooking energy. We encourage the development of a proactive culture of “safety and well-being” and we are proud to be certified as a Great Place to Work (GPTW).

Our Life Cycle Assessment (LCA) is positively impacted by our use of renewable hydroelectric power, our lightweight cylinders which reduce carbon emissions during transportation and their 22+ years proven lifetime. Furthermore, we are ISO 14001 certified (Environmental Management). Guided by our Sustainability strategy and Science-Based Targets, our focus will remain on continuously improving our environmental footprint.

In accordance with our values, Integrity and Drive, and in partnership with our customers, suppliers and industry institutions such as the World LPG Association (WLPGA), Liquid Gas Europe, Ibero American LPG Association (AIGLP) and USA’s National Propane Gas Association (NPGA), we aim at setting the highest standards for reliable products and responsible business operations. In addition, Hexagon is a member of the UN Global Compact.

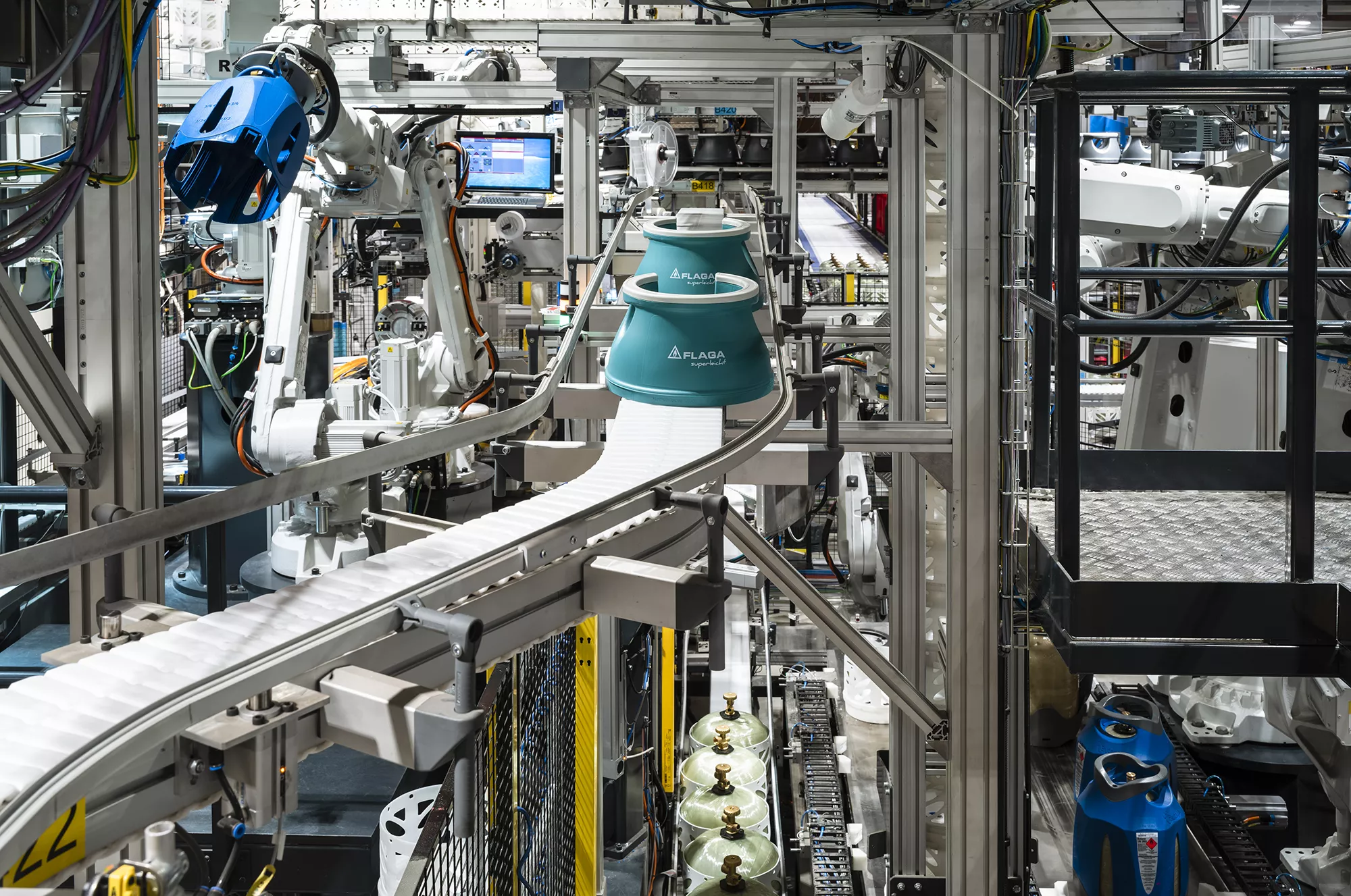

As technology pioneers for composite LPG cylinders, we have over the last two decades built a highly resource efficient world-class manufacturing capability. As such, we are ISO 50001 certified for energy management.

Our R&D is driven by our sustainability goals which aim to keep improving our products environmental footprint throughout the value chain.

Our Environmental Product Declarations (EPD) are proof of our commitment to transparency and focus on science-based information to evaluate the environmental performance of our products.

Hexagon Group takes ethical, environmental, social, and governance issues into account in every business decision we make

We focus on six SDG's that are closely linked to our core operations and business strategy.

Some of our research projects, partly funded by The Norwegian Research Council:

The aim of the project is to achieve advanced use of Big Data from our fully automated and digitized manufacturing plant to strive towards Industry 4.0 and manufacturing excellence. The project is in cooperation with the industrial partner BENTELER and with NTNU and SINTEF as research partners.

The aim of the project is to ensure a future circularity for mechanically recycled composite materials into the production of new demanding composite products and applications. The project is in cooperation with different industrial partners in Norway, including Amiblu, Vello, Steni and Ecofiber, and with SINTEF as research partner.

The aim of the project is to predict the lifetime of advanced composite products by using multivariat analysis and develop algorithms based on both accelerated and real-life climatically aged composite structures. The project is in cooperation with NTNU as research partner.

The aim of the project is to explore the potential of utilizing composite materials in advanced applications to replace brass for improved sustainability of our product system. The project is in cooperation with the industrial partner Isiflo and SINTEF as research partner.

Some of our research projects, partly funded by different institutions:

The aim of the project is to establish a platform for the end of life processing of our composite cylinders in high value products. The project is in cooperation with multiple industrial partners in Norway and with Sintef & NTNU as research partner.

The aim of the project is to recycle the thermoplastic material used in our products inhouse and in spare parts. The project is in cooperation with the industrial partner Norner and the Future Materials catapult.